Equipment technical parameters (main distinguishing parameter identification background color)

|

|

project |

Jiangxi Meifei Environmental Protection Technology Co., Ltd |

||

|

1 |

Product model: |

MFR-30P |

MFR-40P |

MFR-40G |

|

2 |

Product Name/Brand: |

Fluid disc separator/MFR |

||

|

3 |

Size: |

1015mm * 622mm * 943mm |

||

|

4 |

Weight: |

≤ 320KG |

||

|

5 |

Working power supply: |

Three phase four wire system 380V |

||

|

6 |

Frequency/rated power: |

50HZ/3KW |

||

|

7 |

Usage environment: |

10-70 |

-10-70 ℃ |

-20-80 ℃ |

|

8 |

Environmental humidity: |

|

≤ 95% |

|

|

9 |

Centrifugal cylinder speed: |

8000 r/min |

8000 r/min |

10000 r/min |

|

10 |

Dehydration efficiency: |

0 |

96.10% |

99.80% |

|

11 |

Dehydration method: |

Micro drainage of the sewage box |

Automatic continuous drainage |

High speed automatic continuous drainage |

|

12 |

NAS level: |

6-9 levels |

Level 5-8 |

4-7 levels |

|

13 |

Imported oil pressure: |

Vacuum degree ≤ 0.05Mpa |

||

|

14 |

Maximum output pressure: |

≤ 0.40Mpa |

||

|

15 |

Minimum working pressure: |

≥ 0.15Mpa |

||

|

16 |

Pollutant capacity: |

3Kg |

||

|

17 |

Self suction height: |

≤ 8m |

||

|

18 |

Traffic: |

30-45L/min |

36-50L/min |

36-60L/min (adjustable) |

|

19 |

Oil viscosity range: |

32-320 # oil products are applicable |

||

|

20 |

Moisture content: |

/ |

≤ 500PPM |

≤ 200PPM |

|

21 |

Gas content: |

No free gas |

||

|

22 |

Applicable fuel tank volume |

Drainage and exhaust oil tank fully applicable |

||

|

23 |

Protection system: |

Phase sequence, pressure relief, vibration protection |

Phase sequence, pressure relief, vibration protection |

Soft start protection, phase sequence, pressure relief, vibration protection |

|

24 |

Filter consumption: |

nothing |

||

|

25 |

Sheet metal material: |

304 stainless steel |

||

|

26 |

Upper seal: |

High purity silicon carbide material |

High purity silicon carbide material |

Hard alloy YN8 |

|

27 |

Separation structure: |

Double helix (including disc) |

||

|

28 |

Material of drain valve: |

/ |

Imported alloy aluminum |

Imported alloy aluminum |

|

29 |

Material of separation cylinder: |

|

Imported alloy aluminum |

Imported alloy aluminum |

|

30 |

Lower seal: |

High purity silicon carbide material |

Hard alloy YN8 |

Hard alloy YN8 |

|

31 |

Main component accuracy: |

≤ 0.01mm |

||

|

32 |

Dynamic balance treatment |

have |

||

|

33 |

electrical machinery |

ABB imported motor |

||

|

34 |

Liquid level control switch |

Imported Jiemai |

||

|

35 |

Pressure switch |

Imported Jiemai |

||

|

36 |

Electrical part |

Schneider/Chint/Otonix |

||

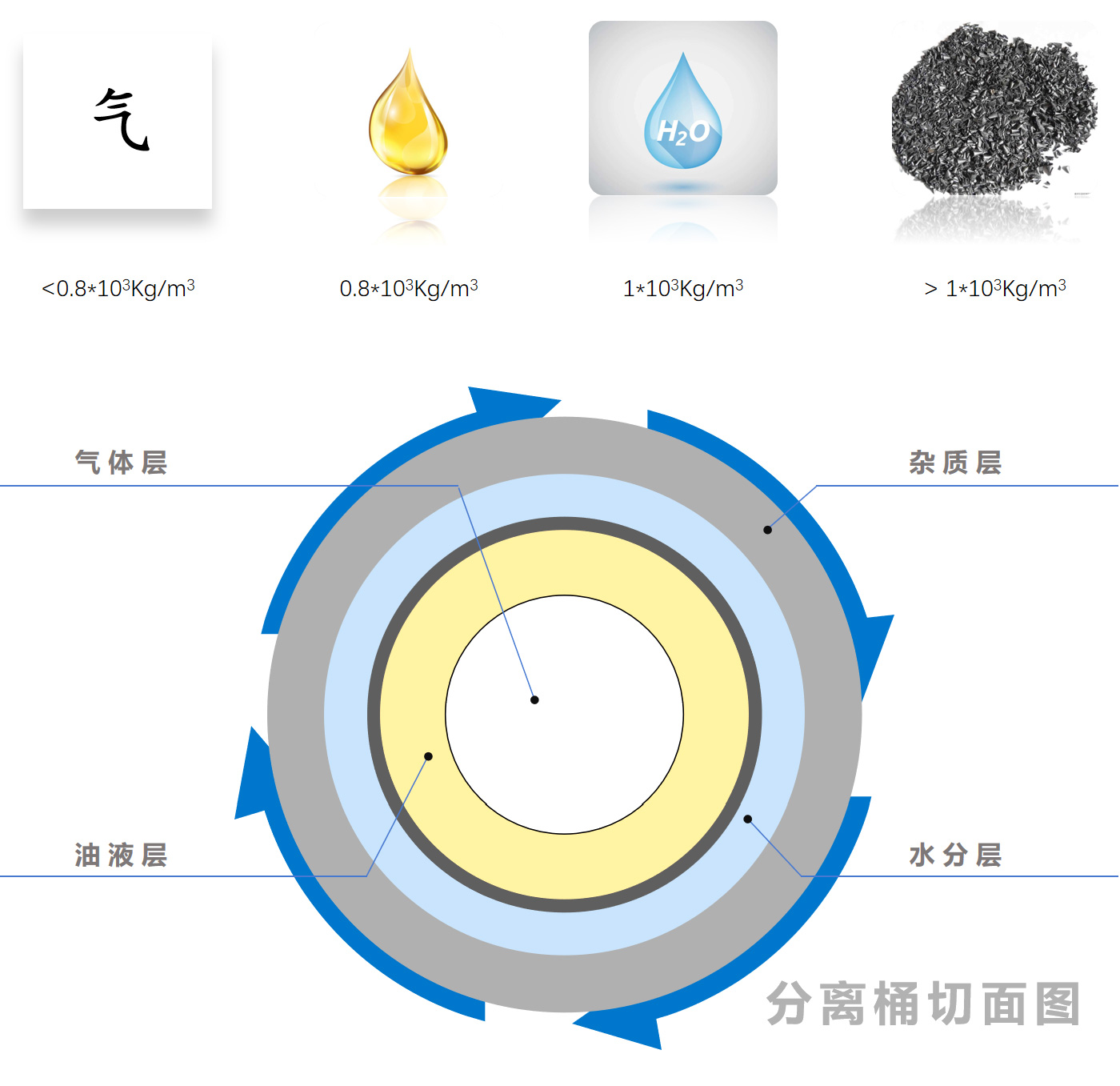

Basic principle of centrifugal oil filter

Separation through different densities of gas, oil, water, and impurities

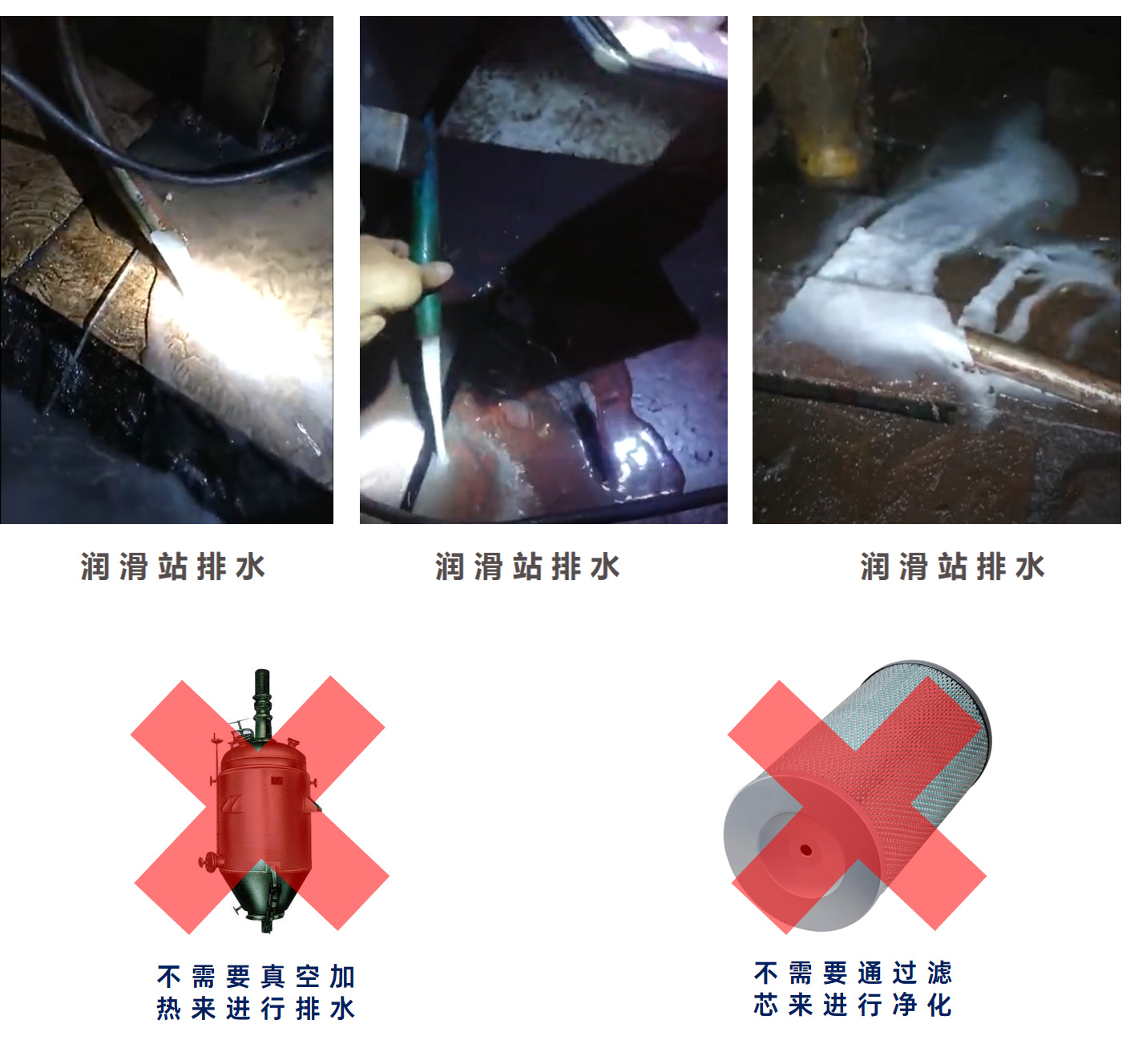

Automatic continuous drainage function

Currently imported purification equipment in China

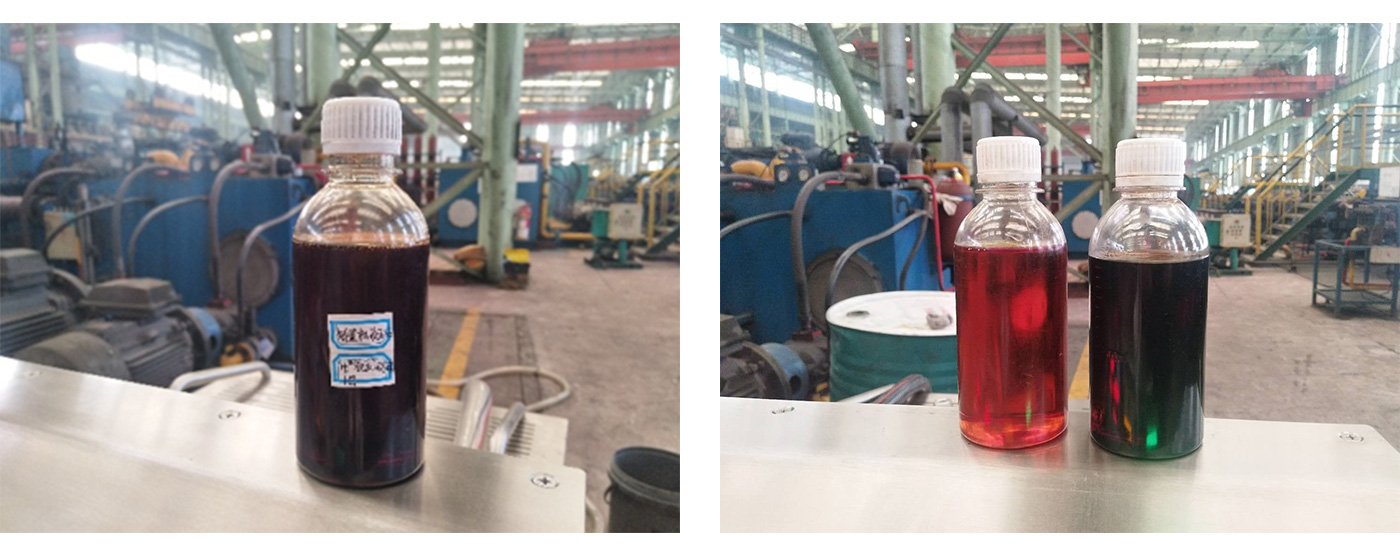

Purification effect

lubricating oil

46 # Anti wear hydraulic oil

Water ethylene glycol

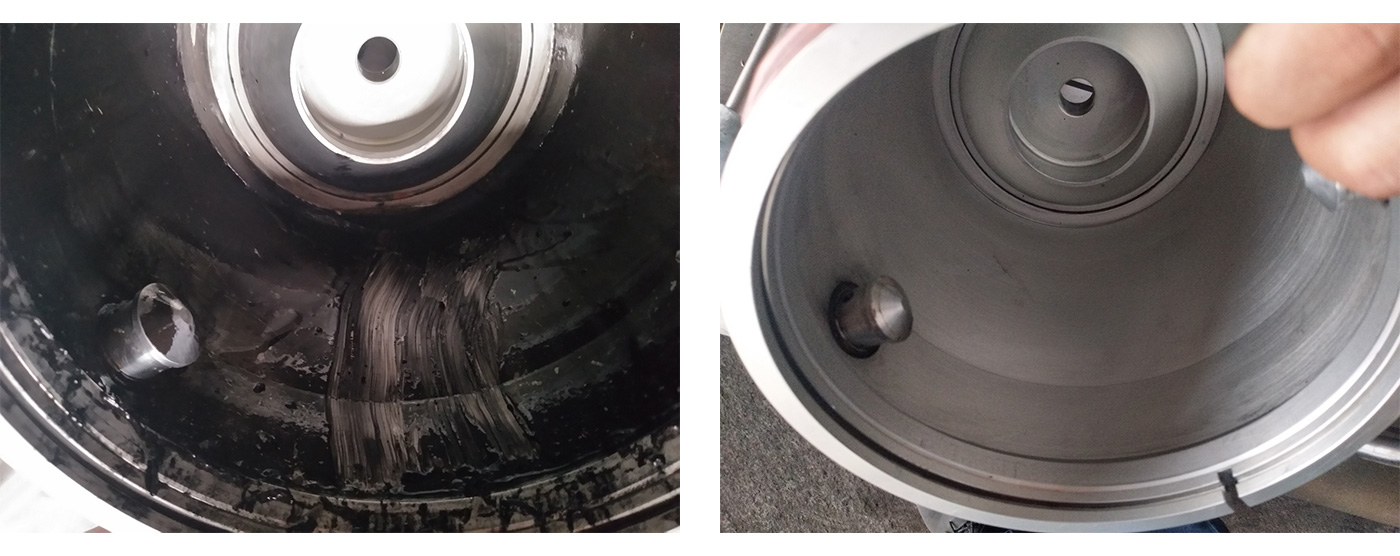

Filtered impurities

Separation of impurities on the inner wall of the drum (before cleaning)Separation of impurities on the inner wall of the drum (after cleaning)

The first cleaning of impurities in the separation bucketThe second cleaning of impurities in the separation bucket

The oil sludge scraped out by the scraperEmulsion adheres to the inner wall of the separation drum

E-mail:MFR_2019@163.com

Address:Building 16, Lithium Battery New Energy Industrial Park, Industrial Avenue, Binjiang Town, Yuanzhou District, Yichun City, Jiangxi Province